Machine Tool Services in Minneapolis, MN

Comprehensive Machine Tool Services for Minnesota Manufacturers

At

C & C Machine Tool Inc., we specialize in the repair, restoration, and maintenance of manual machine tools. We serve customers across the Midwest, including Minnesota, Iowa, North Dakota, South Dakota, Wisconsin, and nearby states. Whether you’re running a production line, a maintenance department, or a job shop, our technicians ensure your equipment performs safely and precisely.

Our team brings hands-on expertise in both mechanical and electrical systems. We service a wide range of equipment—lathes, mills, surface grinders, presses, saws, shears, gearboxes, conveyors, compressors, and more—with an emphasis on accuracy and reliability.

We also support full machine installations, rebuilds, and training programs, ensuring you get the most value out of your equipment.

Why Machine Tool Service Matters

When a key machine goes down, productivity stops. Proper service prevents costly downtime, extends machine lifespan, and protects operator safety. Even the smallest misalignment, worn bearing, or electrical fault can cause quality issues, scrap, or accidents.

Professional maintenance and repair help you:

- Detect early wear before failure

- Maintain consistent tolerances

- Restore spindle and table alignment

- Ensure hydraulic, pneumatic, and electrical systems perform to spec

- Meet safety and compliance standards

C & C Machine Tool Inc. understands that each minute counts. That’s why our repair process emphasizes quick diagnostics, clear communication, and lasting results.

Core Service Categories

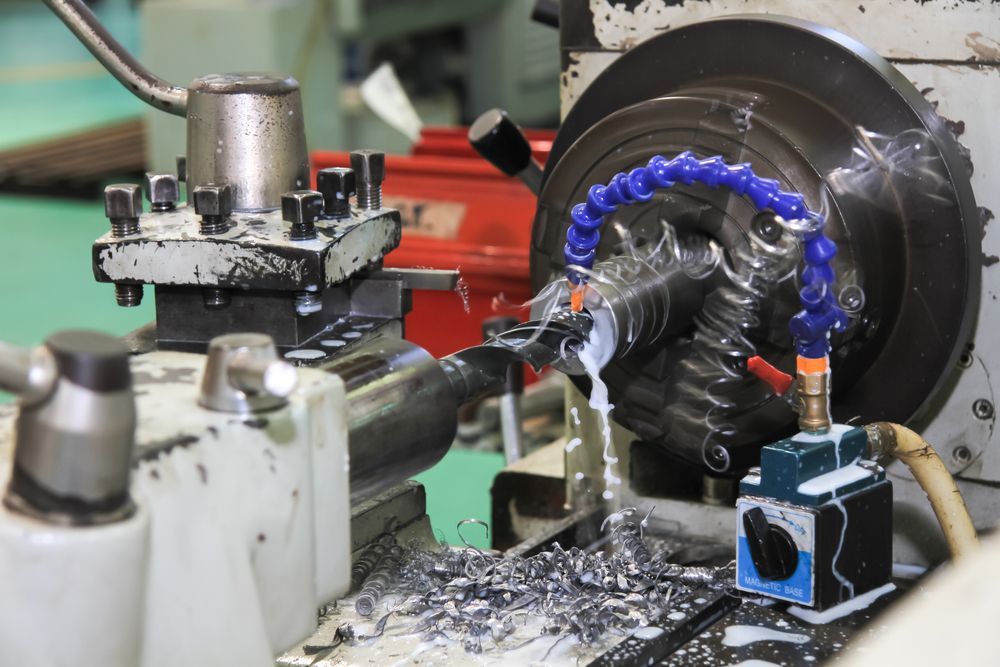

Lathe repairs

From worn bearings to gear failures, our lathe repair services cover headstocks, tailstocks, gearboxes, threading systems, and electrical controls. We handle alignment, feed repairs, and lubrication system restorations to ensure your lathe holds accuracy and finish.

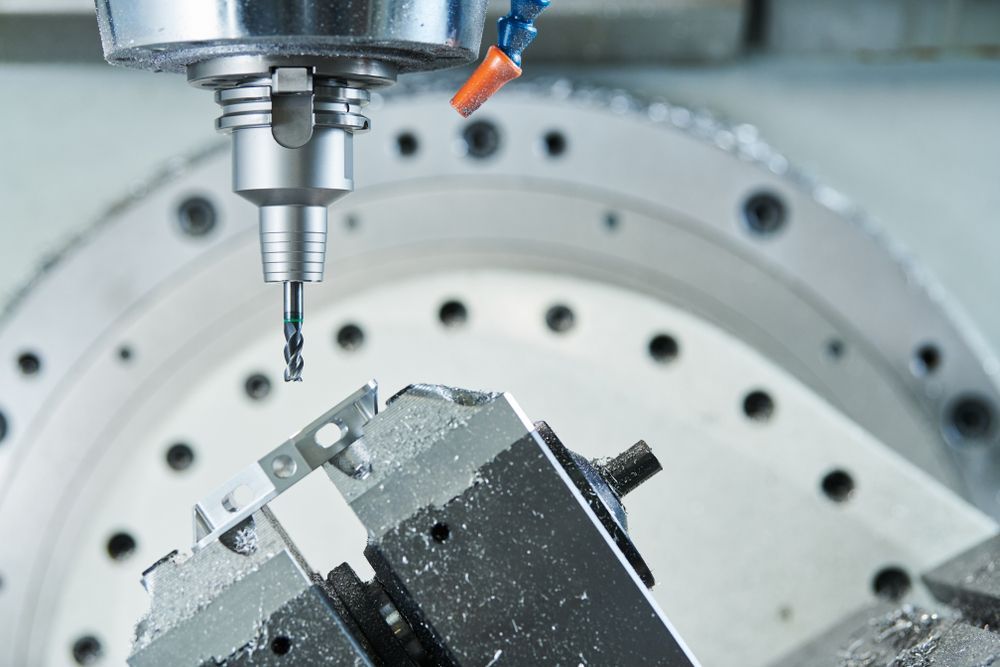

Milling Machine Repair

Our manual milling machine repairs include complete head rebuilds, spindle replacements, power feed troubleshooting, and knee or saddle adjustments. We realign ways, correct tramming errors, and upgrade systems such as DROs or variable-speed heads for improved performance.

Surface Grinder Repair

Surface finish issues often trace back to spindle, chuck, or table problems. We perform full surface grinder repairs, including, bearing replacement, and alignment to restore precision flatness and parallelism.

Band Saw Repair

A misaligned saw costs material and time. We handle

band saw repair for blade tracking, tensioning, guide adjustment, hydraulic feed control, and motor or gearbox issues—so every cut is clean and consistent.

Metal Shear Repair

We repair metal shears from foot-operated to hydraulic models, focusing on blade alignment, back gauge systems, hydraulics, and safety functions. Proper adjustment ensures accurate, burr-free cuts.

Medical Industry

We provide repair and maintenance services for the precision lathes, mills, and grinders used in manufacturing medical devices, orthopedic implants, and specialized surgical tools.

Preventative Maintenance and Inspection

Preventative maintenance is the backbone of uptime. Regular inspection prevents costly breakdowns by catching small issues early.

Our maintenance programs include:

- Machine cleaning and lubrication

- Precision alignment checks

- Spindle and bearing condition testing

- Hydraulic system inspection

- Electrical and DRO system verification, Mill/PWR

- Safety component checks and calibration

Whether monthly, quarterly, or annual, we tailor schedules to your workload and equipment type.

Machine Installation, Training, and Support

As a certified sales and service provider for major brands—including Sharp, Acer, Kent USA, Kent International, Hardinge, Clausing, Acra, LeBlond Ltd, Scotchman, Dapra, Gorilla Mill, Curtis Fluids, Unist, and Acu-Rite Solutions—we offer end-to-end support.

Services include:

- Delivery and setup

- Leveling and alignment

- Power and control integration

- Operator and maintenance training

- Ongoing technical support

Our installation process ensures that every new machine is calibrated and performing to manufacturer standards before it goes into production.

Industries We Serve

- Job and tool shops

- Metal fabrication facilities

- Educational and training institutions

- Industrial maintenance departments

- Manufacturing and prototyping labs

Each client benefits from our customized repair solutions, responsive scheduling, and deep equipment knowledge.

Our customers span multiple sectors, including:

Our Service Process

Diagnosis

Our technician inspects the unit on-site to identify mechanical, hydraulic, or electrical faults.

Repair & Verification

Once approved, we complete the repair, test alignment, and verify performance.

This structured approach ensures accuracy, accountability, and minimal downtime.

FAQs

Do you service legacy and newer manual machines?

Yes. We work on legacy lathes, knee mills, surface grinders, presses, and more, as well as newer manual equipment with modern DROs and power feeds.

Can you help source parts for older machines?

In most cases, yes. If OEM parts are unavailable, we can propose compatible components or engineered solutions to restore function safely.

Do you offer installation and training for new machines?

Absolutely. We install, level, align, and commission machines, then provide operator and maintenance training tailored to your workflow.

What areas do you cover?

We serve customers across the Midwest, including Minnesota, Iowa, North Dakota, South Dakota, Wisconsin, and nearby states. Contact us to discuss on-site service at your location.

How fast can you respond?

We prioritize breakdowns and aim to minimize downtime. Call (763) 910-3811 during business hours to get on the schedule.

Contact Us

For prompt service, contact C & C Machine Tool Inc. today. Call (763) 910-3811 or email mandy@ccmachinetoolinc.com to schedule diagnostics, preventive maintenance, or machine installation. Visit our facility at (763) 910-3811th Lane Northeast, Blaine, Minnesota, 55449, open Monday through Friday, 7:00 a.m.–5:00 p.m.

Our team is ready to restore your equipment, protect your uptime, and keep your production running efficiently.