Conveyor System Repair in Minneapolis, MN

See Our Precision Work in Action

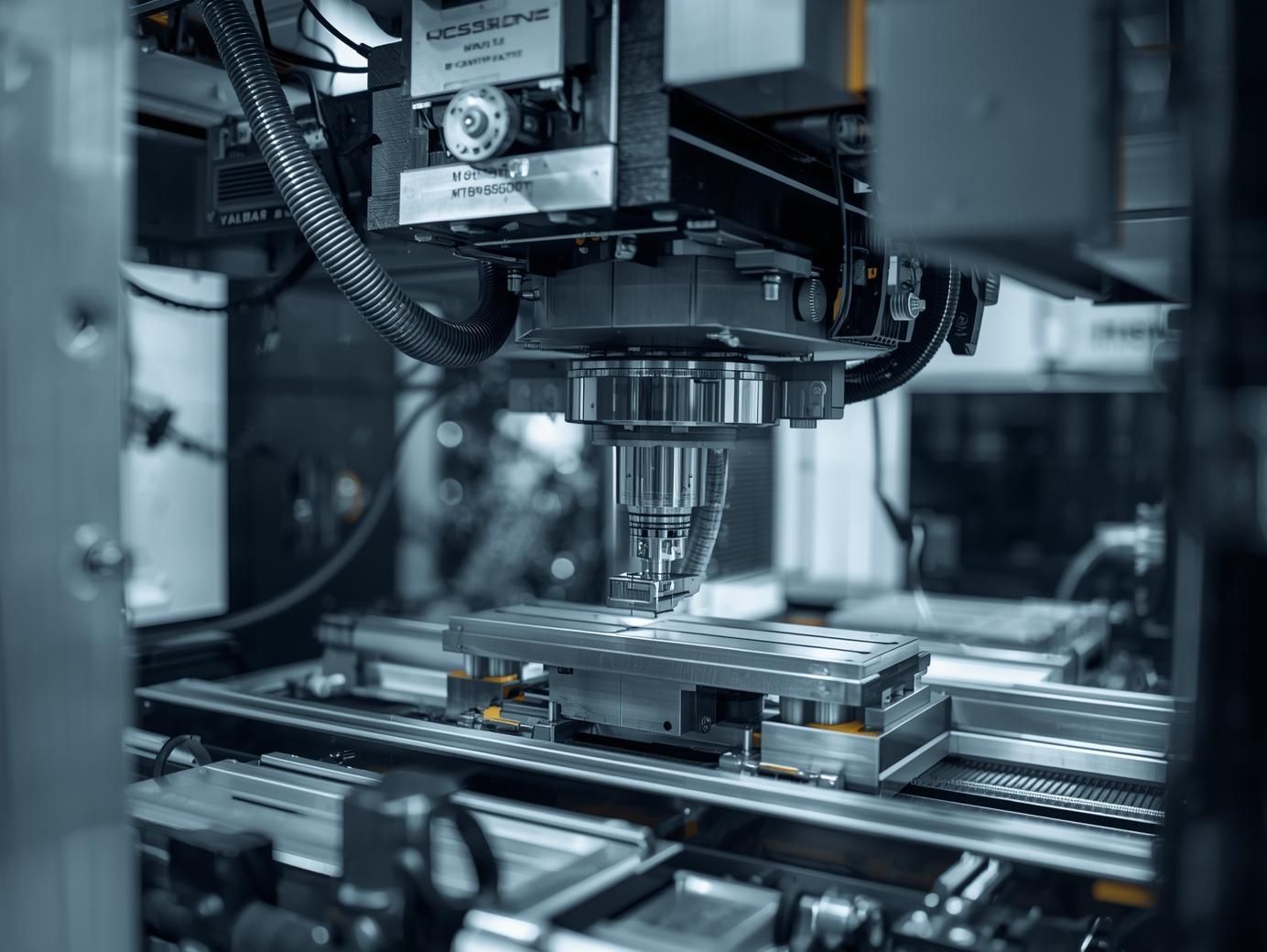

At C & C Machine Tool Inc., every repair and rebuild we perform reflects our dedication to precision, craftsmanship, and reliability. Our gallery page showcases the quality of our work—ranging from lathe and mill repairs to full machine tool rebuilds and installations throughout Minnesota.

Since 2015, we’ve helped countless manufacturers, maintenance teams, and fabrication shops keep their machines running at peak performance. This gallery offers a closer look at what we do best: diagnosing problems, restoring equipment, and extending the lifespan of valuable machinery.

Our Expertise, Captured in Every Image

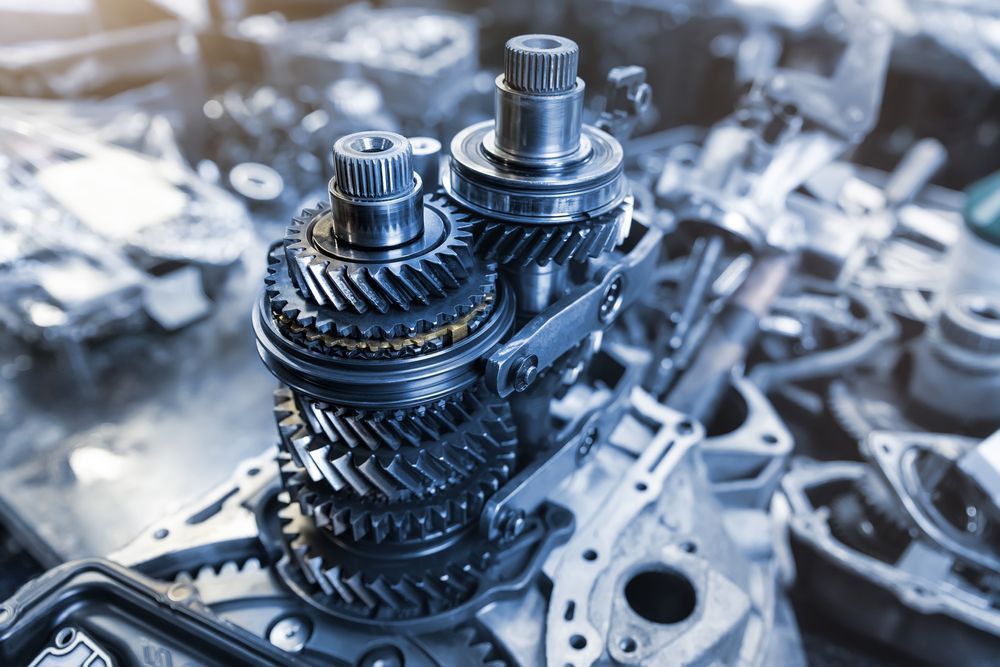

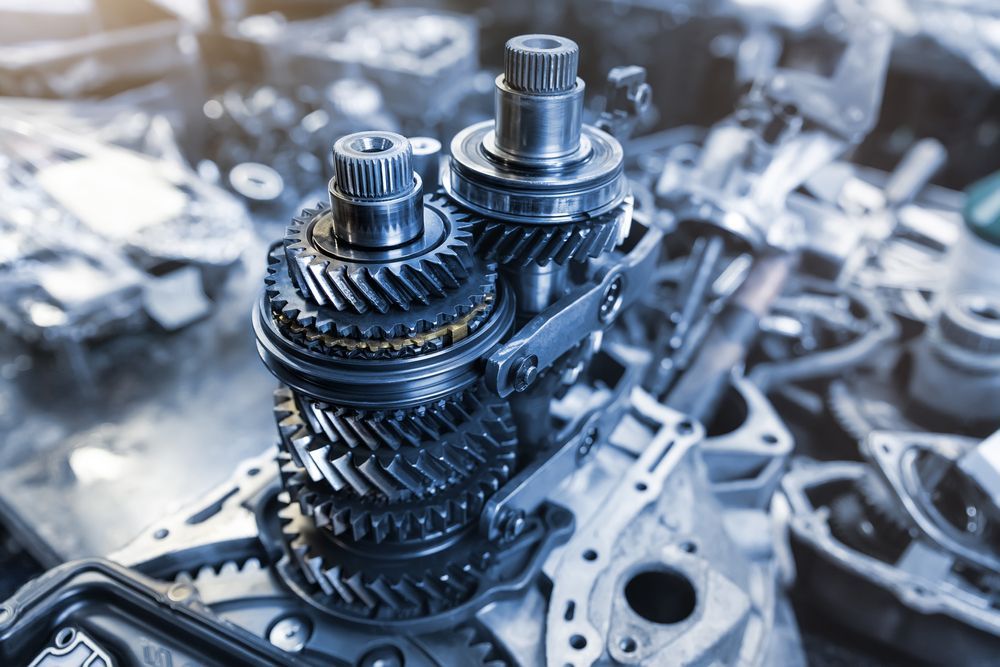

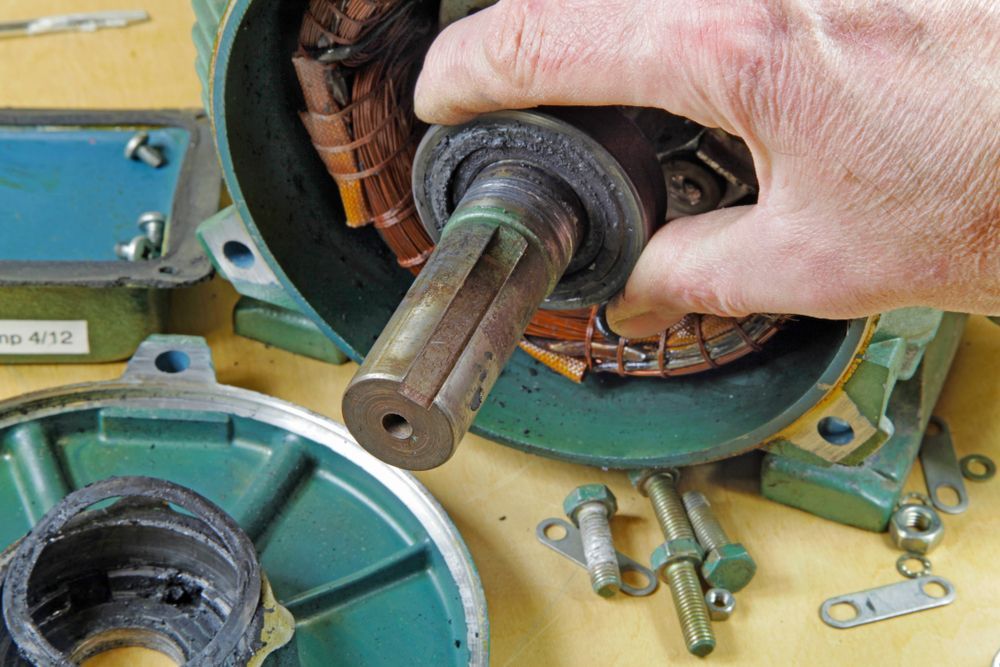

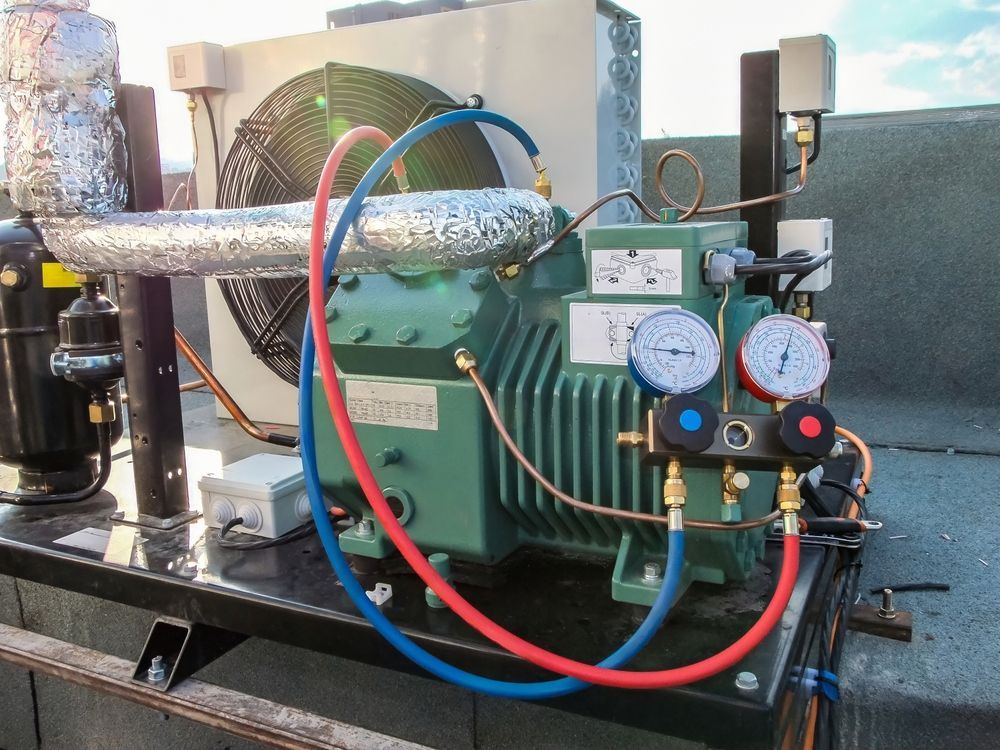

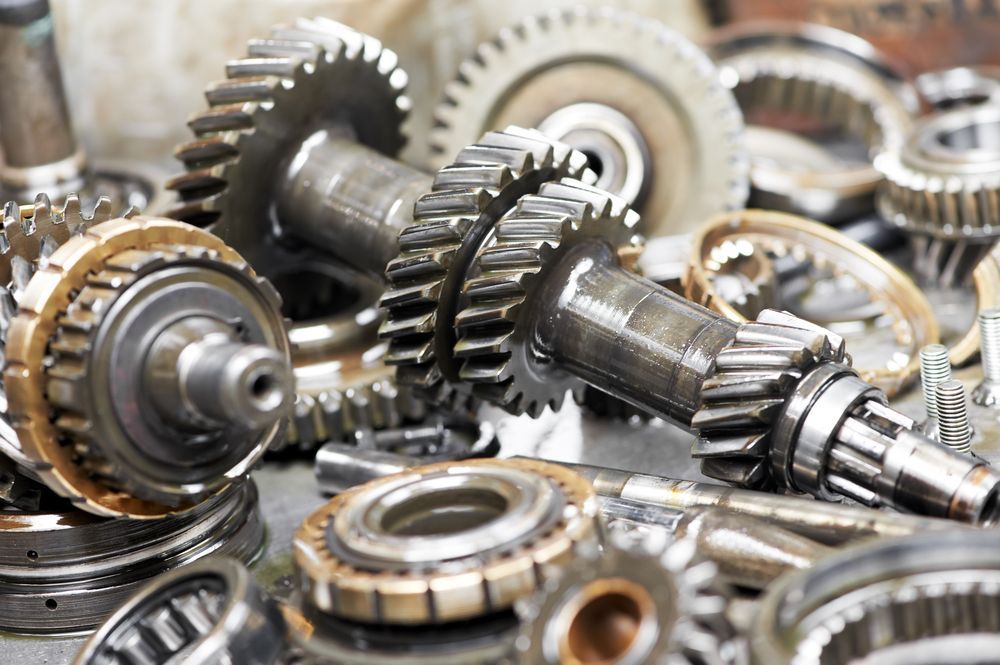

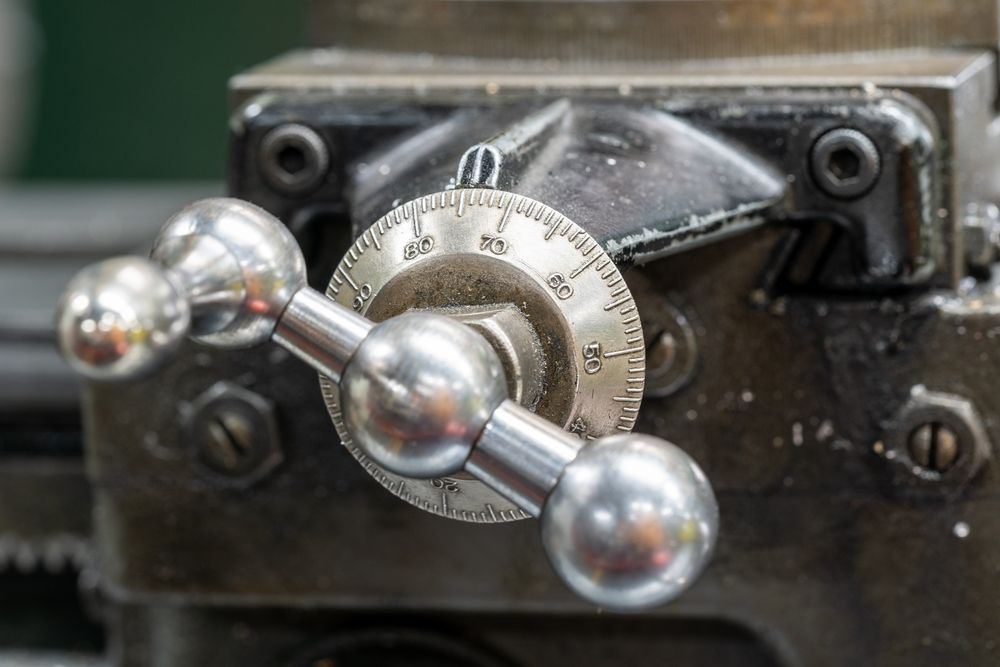

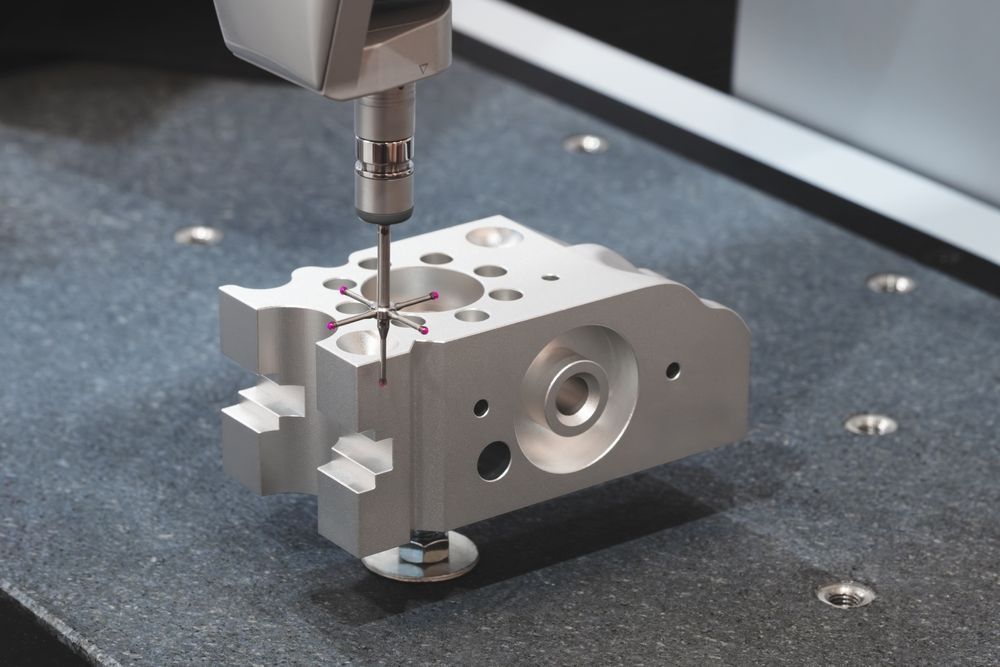

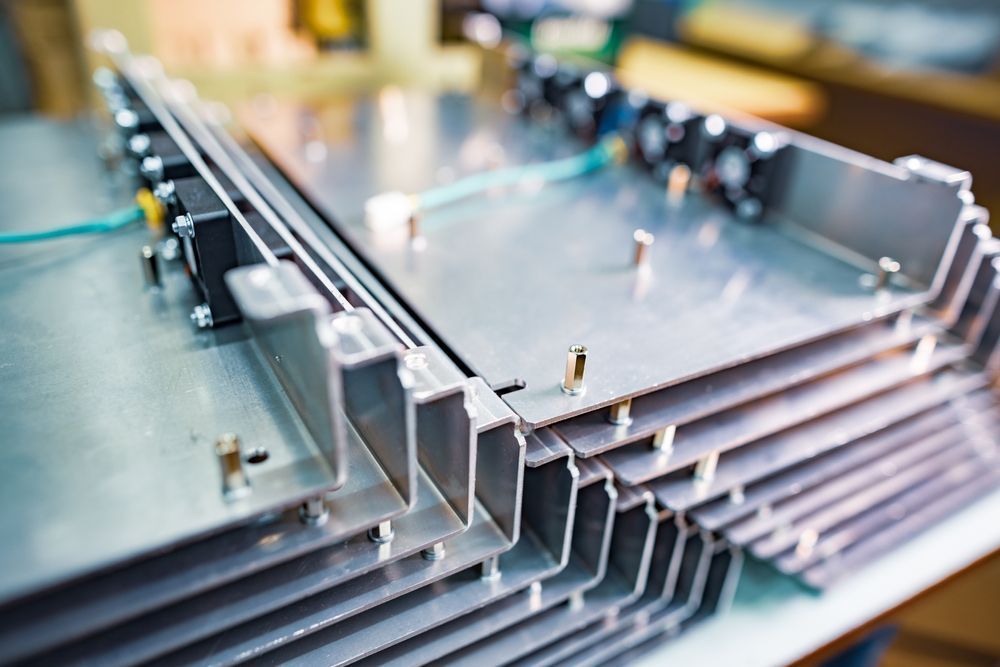

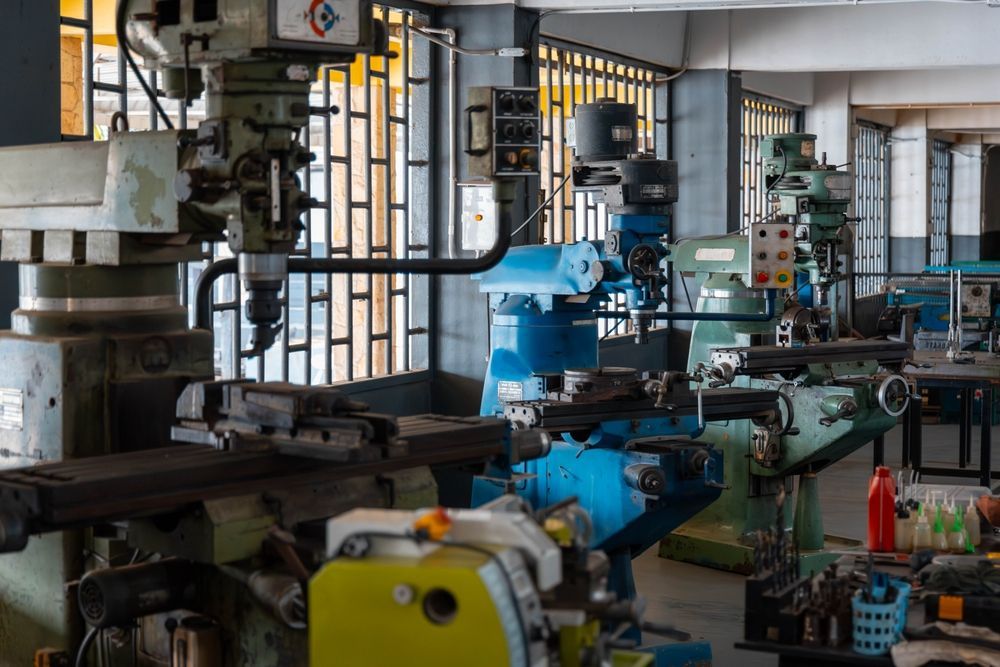

Each photo in our gallery demonstrates the care and technical accuracy that go into every project we complete. We service and rebuild all types of manual and industrial machines, including:

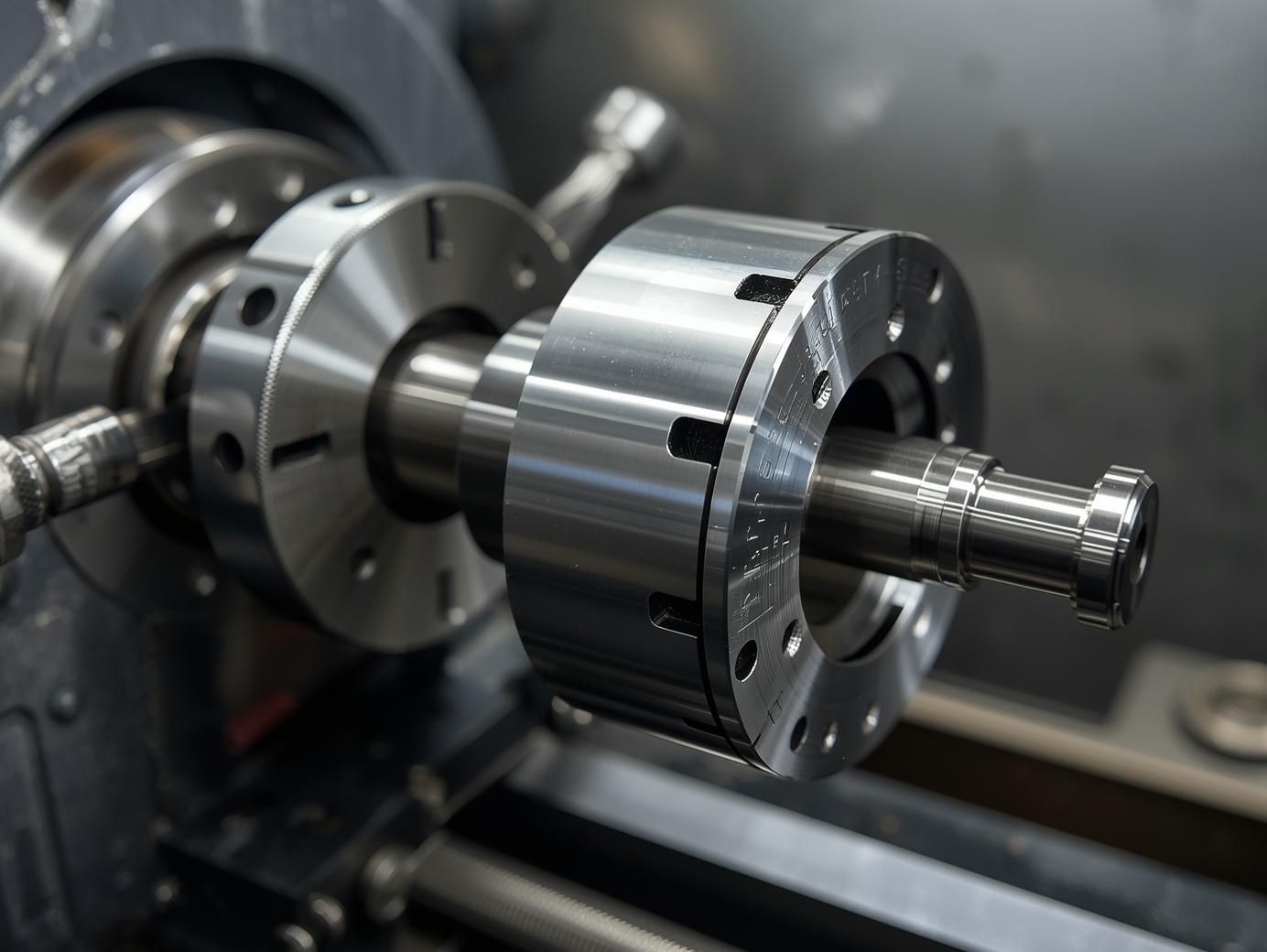

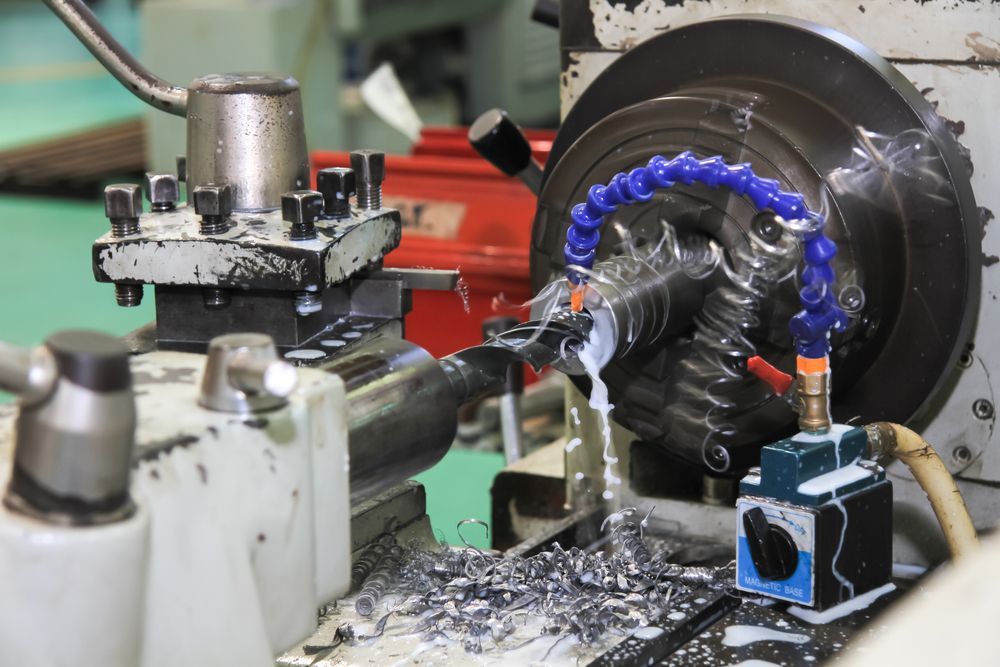

- Lathes: Full mechanical and electrical repairs, bearing replacements, and alignment verification.

- Milling Machines: Head rebuilds, spindle repairs, DRO installations, and power feed calibration.

- Surface Grinders: Chuck resurfacing, spindle repairs, and hydraulic table realignment.

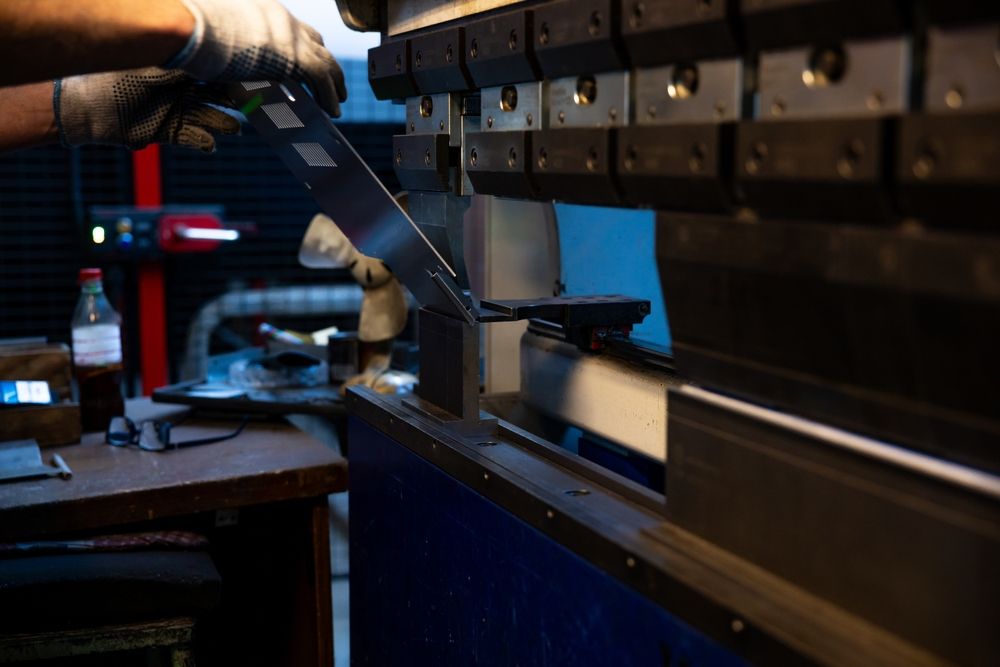

- Presses (Hydraulic, Brake, and Punch): Seal replacements, ram alignment, pump rebuilds, and tonnage verification.

- Saws and Shears: Gearbox service, blade guide alignment, hydraulic calibration, and safety system checks.

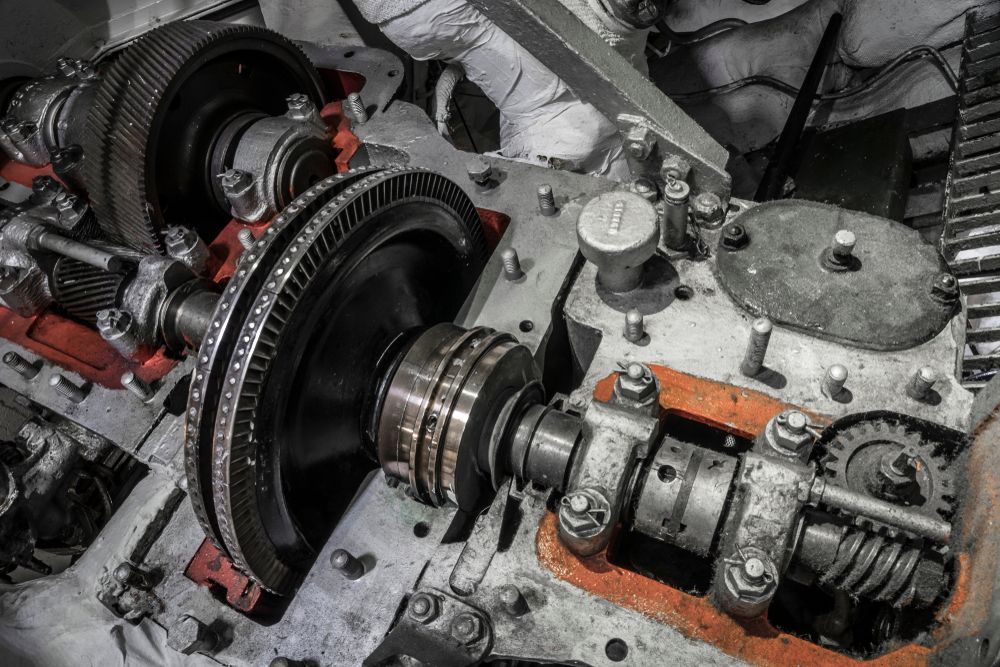

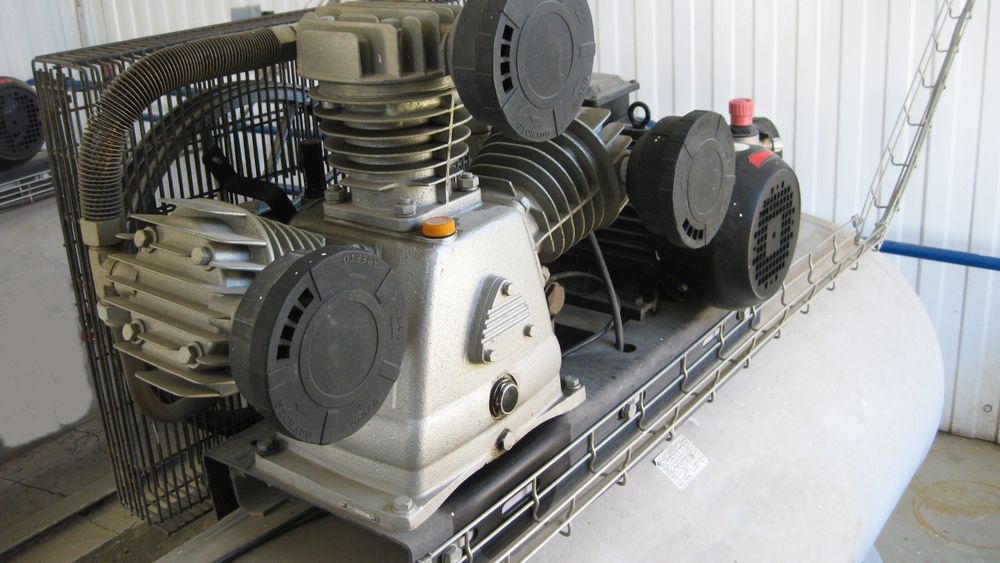

- Conveyors, Gearboxes, Compressors, and Motors: Complete mechanical and electrical restoration with performance testing.

Our gallery highlights the precision behind every step of our process—from teardown and inspection to final testing and installation.

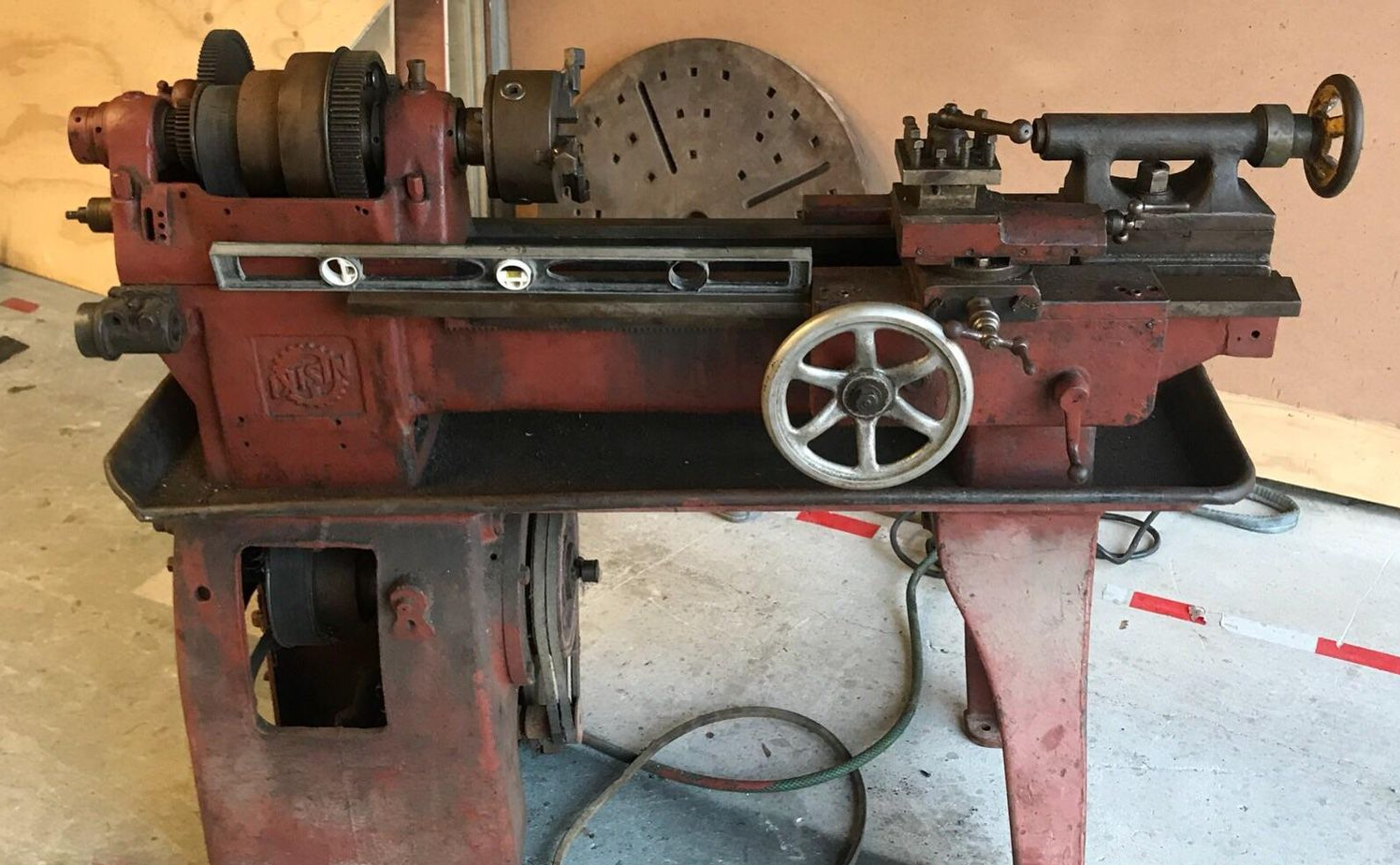

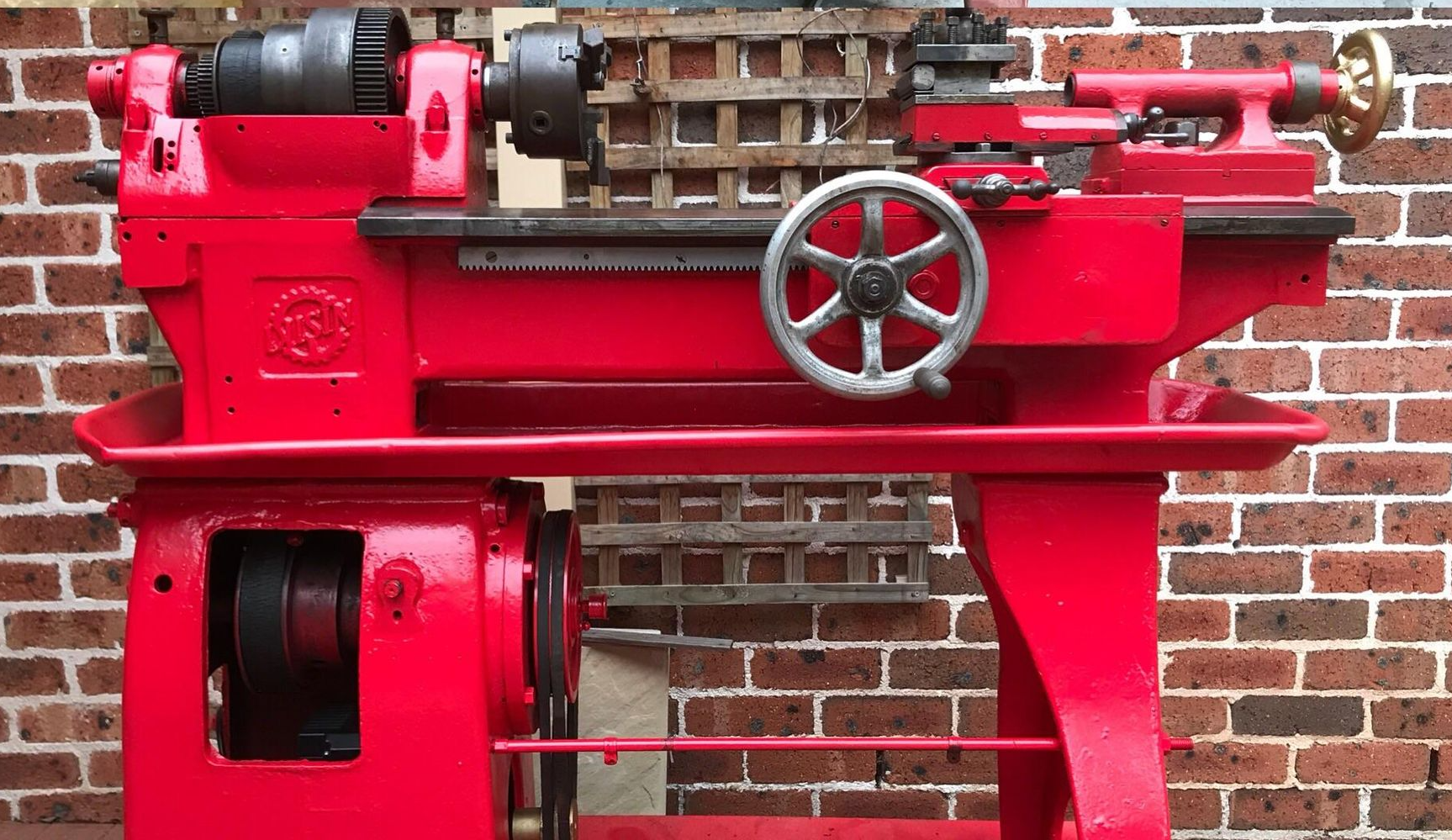

Before & After: Machine Restoration Examples

Example Projects

- Lathe Overhaul: Complete headstock rebuild, spindle bearing replacement, and full tram alignment for a Minneapolis tool shop.

- Milling Machine Restoration: Sharp knee mill reconditioned with new spindle bearings, fresh lubrication system, and DRO installation.

- Hydraulic Press Rebuild: Cylinder resealing, pump replacement, and tonnage calibration for a heavy-fabrication client.

- Surface Grinder Service: Chuck resurfacing, new spindle bearings, and flatness verification within .0002”.

- Band Saw Alignment: Blade guide adjustment, gearbox reseal, and vibration correction for a manufacturing facility.

Every project represents a commitment to returning machines to “as-new” accuracy—both mechanically and cosmetically.

Before: Many machines arrive at our shop with worn bearings, misaligned components, hydraulic leaks, or outdated electrical systems.

After: Once serviced, they leave operating with restored precision, proper lubrication, smooth motion, and reliable control systems.

On-Site and In-Shop Work

Our technicians perform repairs both

in-shop and on-site, depending on the type and size of the equipment.

In-Shop Repairs: Full rebuilds, precision alignments, and complex component replacement performed at our Minneapolis facility.

On-Site Service: Emergency breakdown support, hydraulic repairs, and minor electrical or mechanical troubleshooting performed directly at your location.

Each image in our gallery reflects our versatility—whether it’s a single machine restoration or an entire production line repair.

Equipment Installation & Calibration

Beyond repairs, C & C Machine Tool Inc. provides professional installation and calibration services for newly purchased machines.

Our gallery features projects where our technicians:

- Delivered, leveled, and anchored new mills and lathes.

- Installed

Acu-Rite DRO systems for precise digital measurement.

- Calibrated hydraulic and press systems to ensure full tonnage accuracy.

- Performed safety inspections and operator training for new installations.

These photos show our commitment not just to precision, but also to helping customers achieve seamless integration of their new equipment.

The C & C Difference in Every Detail

Each machine we service tells a story—one of durability, engineering, and trust. Our gallery highlights:

Our gallery features projects where our technicians:

- Clean, organized repair environments.

- Proper handling and protection of precision components.

- Attention to detail during assembly and calibration.

- Final performance verification and testing.

We treat every piece of equipment as if it were our own, ensuring our clients receive dependable machines capable of years of continued service.

A Glimpse Inside Our Facility

Located in

Minneapolis, Minnesota, our fully equipped workshop includes:

- Precision metrology and alignment tools.

- Dedicated rebuild bays for mechanical and electrical systems.

- Component cleaning and degreasing stations.

- Hydraulic testing and calibration equipment.

- Controlled work areas for DRO and control system installations.

The photos in this gallery capture both our facility and the craftsmanship that defines every repair performed by C & C Machine Tool Inc.

FAQs

Do you take on full machine rebuilds or only repairs?

Yes, we perform full mechanical and electrical rebuilds, restoring machines to factory accuracy.

Can I see examples of specific machine brands you’ve worked on?

Yes. Our gallery features repairs on brands like Sharp, Acer, Kent USA, Hardinge, Clausing, and LeBlond Ltd.

Do you document the repair process for customers?

Absolutely. We provide progress photos, inspection reports, and performance data upon request.

Can you feature my machine in your gallery after service?

Yes—with customer permission, we occasionally showcase standout rebuilds in our gallery.

Is your gallery updated regularly?

Yes. We add new projects as they are completed to reflect our latest work and capabilities.

Contact Us

Interested in seeing our work up close or scheduling your own machine repair? Visit our Minneapolis facility or contact C & C Machine Tool Inc. today.

Phone:

(763) 910-3811

Email:

mandy@ccmachinetoolinc.com

Address:

(763) 910-3811th Lane Northeast, Blaine, Minnesota, 55449

Hours: Monday–Friday, 7:00 a.m.–5:00 p.m.

Explore the craftsmanship, precision, and dedication that make C & C Machine Tool Inc. a trusted partner for machine tool repair, restoration, and sales across Minnesota.