Milling Machine Repair in Minneapolis, MN

Expert Manual Milling Machine Repairs

Precision milling requires a machine that’s perfectly aligned and mechanically sound. When your mill begins to chatter, lose accuracy, or show uneven finishes, it’s time for expert service. At

C & C Machine Tool Inc., we specialize in

manual milling machine repair, head rebuilding, and alignment across the Midwest, including Minnesota, Iowa, North Dakota, South Dakota, Wisconsin, and nearby states.

Since 2015, our family-owned company has provided complete mill repair solutions—from spindle bearing replacements and quill repairs to full knee and saddle realignments. Our technicians understand every detail of Bridgeport-style and similar manual mills, restoring machines to their original precision and reliability.

Why Milling Machine Maintenance and Repair Matter

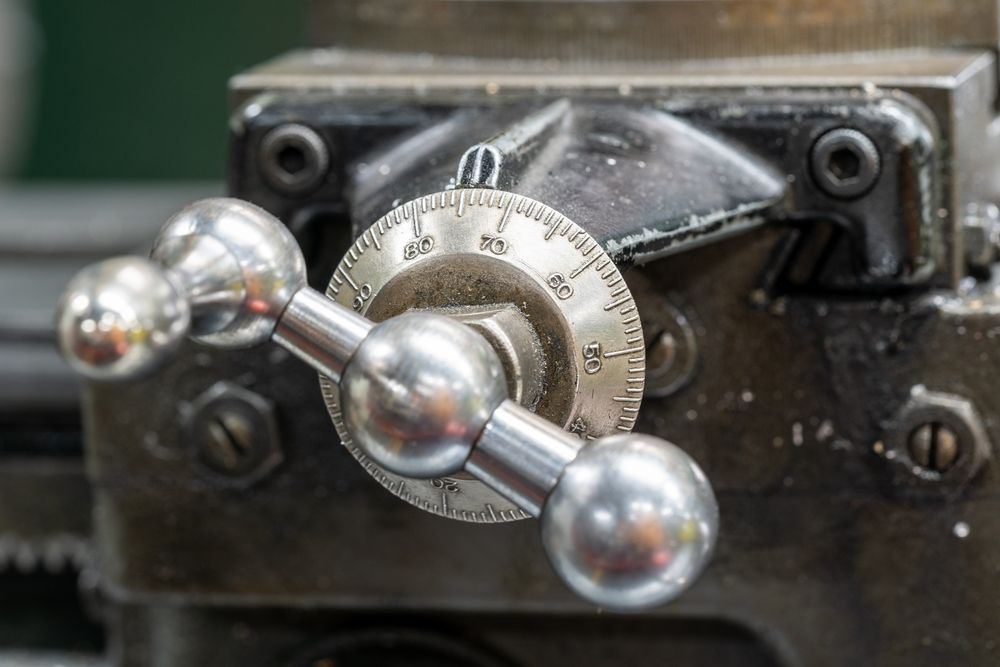

A milling machine is one of the most heavily used assets in any shop. Even minor wear in the spindle, column, or table can create compounding errors that ruin tolerances and surface finishes. Preventive maintenance and timely repairs help:

- Eliminate chatter and vibration

- Maintain tight part tolerances

- Extend spindle, bearing, and way life

- Improve surface finish and repeatability

- Prevent expensive component failures

At C & C Machine Tool Inc., our approach blends deep technical expertise with modern metrology practices. Every repair is performed with accuracy and verified under test cutting conditions before your mill goes back into service.

Common Milling Machine Issues We Fix

Our technicians have extensive experience diagnosing and correcting problems across all makes and models of manual mills. Common issues we address include:

- Head noise or excessive vibration

- Spindle bearing or drawbar wear

- Feed clutch or gear slippage

- Quill and spindle binding or drift

- Table and saddle backlash

- Knee or column wear and misalignment

- Electrical and motor issues

- DRO and power feed malfunctions, Mill/PWR

- Poor tram or out-of-square table movement

- Lubrication and coolant system failures

Whether your mill is a Sharp, Acer, Kent USA, or Clausing, our repair team can identify the cause and restore performance with precision.

Our Milling Machine Repair Process

Initial Inspection

We begin with a full mechanical and electrical inspection, checking spindle play, column alignment, and backlash across all axes.

Diagnosis and Reporting

Each issue is documented, with detailed repair recommendations and transparent pricing.

Head and Spindle Service

We disassemble, clean, and rebuild heads, replacing bearings, drawbars, gears, and feed clutches as needed.

Alignment and Calibration

Using precision indicators, we tram the head, level the table, and align the column to restore geometric accuracy.

Testing and Verification

After reassembly, the machine undergoes full operational testing and surface finish verification.

This structured process ensures your milling machine operates with restored power, precision, and smoothness.

Milling Machine Brands We Service

C & C Machine Tool Inc. services a wide range of manual mills and their variants, including:

- Sharp

- Acer

- Kent USA

- Kent International

- Clausing

- Acra

- Bridgeport-style mills and clones

- Hardinge

- LeBlond Ltd

We stock or source high-quality OEM and aftermarket replacement components, ensuring reliable results and long-term operation.

Specialized Head and Spindle Repair Services

The milling head is the heart of the machine—and one of the most common sources of performance loss. Our head repair and rebuild services include:

- Complete spindle teardown and bearing replacement

- Gear, pulley, and clutch rebuilds

- Back gear and belt drive servicing

- Quill and drawbar adjustments

- Variable-speed head repairs

- Motor and electrical component testing

We restore smooth power delivery, eliminate noise, and correct spindle runout to deliver consistent cutting performance and better surface finishes.

Additional Milling Machine Services

- Acu-Rite DRO installation and calibration, Mill/PWR

- Power feed system setup or repair

- Table and knee scraping and reconditioning

- Way regrinding coordination

- Preventive maintenance programs

- Training for operators and maintenance staff

Our comprehensive service approach allows your team to focus on production while we handle the precision maintenance your machines require.

Beyond core repairs, we offer services that extend the life and efficiency of your mill:

Industries We Serve

- Machine and job shops

- Fabrication and prototyping facilities

- Manufacturing and industrial maintenance departments

- Tool and die operations

- Educational institutions and trade schools

Every customer receives detailed communication, dependable scheduling, and workmanship that meets or exceeds industry standards.

Our milling machine repair services support a variety of clients across the Midwest, including Minnesota, Iowa, North Dakota, South Dakota, Wisconsin, and nearby states.:

FAQs

Do you repair only Bridgeport-style mills?

No. We repair a variety of vertical and horizontal manual mills, including Sharp, Acer, Kent, Clausing, and more.

Can you realign a mill that’s producing taper?

Yes. We perform full tram and column realignment to correct taper or off-axis issues.

Do you offer on-site service?

Yes. Many head, motor, and alignment repairs can be completed at your facility to minimize downtime.

Can you retrofit my mill with a new DRO or power feed?

Absolutely. We offer professional installation of Acu-Rite and other top-tier systems for enhanced productivity.

How often should a mill be serviced?

For high-usage machines, quarterly inspections are ideal. Annual alignment checks are recommended for general maintenance.

Contact Us

Ensure your milling machines stay accurate, reliable, and ready for production. Contact C & C Machine Tool Inc. today for expert milling machine repair in Minneapolis and throughout Minnesota.

- Phone:

(763) 910-3811

- Email:

mandy@ccmachinetoolinc.com

- Address:

(763) 910-3811th Lane Northeast, Blaine, Minnesota, 55449

- Hours: Monday–Friday, 7:00 a.m.–5:00 p.m.

From head rebuilds and spindle replacements to complete realignments, our team restores your equipment with precision and care—so every part you machine meets your highest standards.