Brake Press Repair in Minneapolis, MN

Expert Brake Press Service and Maintenance

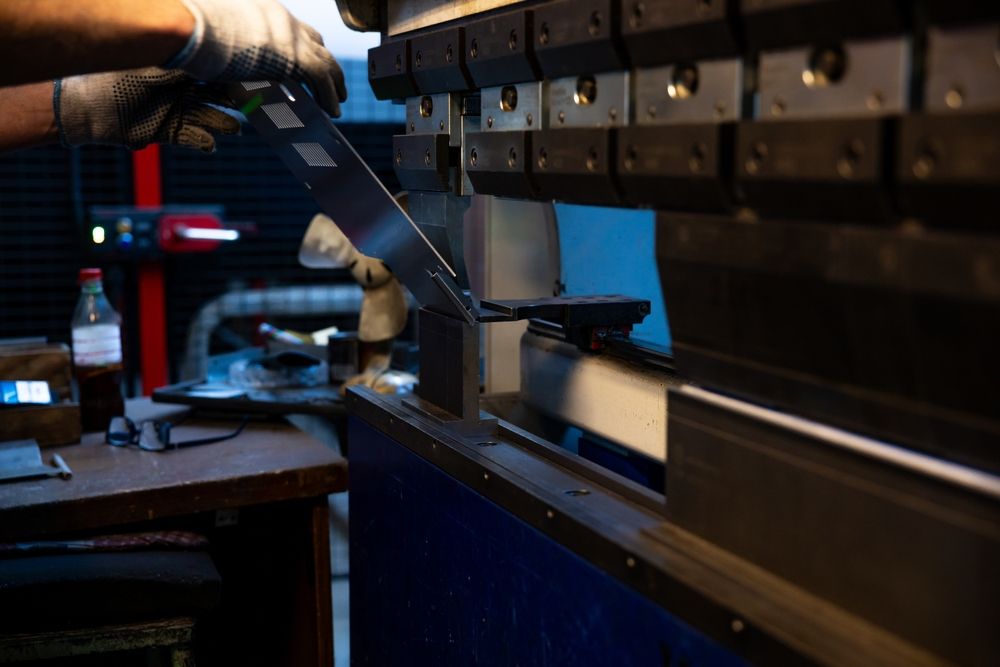

A properly operating brake press is vital for accurate bends and safe production. When the ram misaligns, tonnage drops, or hydraulic systems leak, both productivity and part quality suffer.

C & C Machine Tool Inc. provides

comprehensive brake press repair and maintenance services for industrial and fabrication facilities throughout Minneapolis and greater Minnesota.

Since 2015, our family-owned company has specialized in repairing, rebuilding, and maintaining hydraulic and mechanical brake presses, helping manufacturers extend machine life and maintain consistent forming accuracy. Every repair we perform focuses on restoring precision, performance, and operator safety.

Why Brake Press Repair and Maintenance Matter

Brake presses are precision machines that depend on consistent pressure, alignment, and control. Over time, mechanical stress and hydraulic wear can cause uneven bends, slower operation, and potential safety hazards.

Regular professional repair ensures:

- Accurate bends and repeatable forming

- Full hydraulic and mechanical tonnage restoration

- Reduced vibration and ram misalignment

- Improved safety and performance

- Longer machine lifespan and reliability

C & C Machine Tool Inc. takes a detail-oriented approach to service—diagnosing the root cause of performance issues and restoring each press to factory accuracy.

Common Brake Press Issues We Repair

Our technicians have decades of combined experience servicing all types of hydraulic and mechanical brake presses. Common problems we resolve include:

- Ram or bed misalignment

- Hydraulic cylinder leaks

- Uneven tonnage or ram deflection

- Pump and valve malfunctions

- Back gauge misalignment

- Electrical control and switch failures

- Pressure loss or slow operation

- Cracked seals and fittings

- Excessive vibration or noise

- Operator safety interlock issues

We provide both on-site service and in-shop rebuilds, depending on the press size and complexity of the repair.

Our Brake Press Repair Process

Inspection and Assessment

We begin with a detailed evaluation of the hydraulic system, ram alignment, back gauge calibration, and control performance.

Diagnosis and Estimate

After inspection, you’ll receive a clear quote outlining recommended repairs, parts, and estimated turnaround.

Hydraulic and Mechanical Repair

We rebuild or replace cylinders, seals, valves, pumps, and fittings. Mechanical linkages are inspected and adjusted to eliminate play or deflection.

Electrical Testing and Safety Verification

Controls, limit switches, and safety interlocks are tested and repaired for compliance and reliability.

Alignment and Calibration

The ram and bed are realigned and leveled to ensure even pressure across the full bending width.

Performance Verification

After reassembly, we perform test bends to confirm accuracy, tonnage, and repeatability.

This process guarantees consistent operation, precise forming, and dependable safety performance.

Brake Press Brands We Service

C & C Machine Tool Inc. services a wide variety of

manual, hydraulic, and CNC brake press brands, including:

- Scotchman

- Kent USA

- Kent International

- Sharp

- Acer

- Clausing

- Acra

- Hardinge

- LeBlond Ltd

- Other major and legacy brake press manufacturers

Whether your machine is an older manual model or a modern hydraulic press brake, our technicians have the expertise to restore its precision and functionality.

Specialized Brake Press Services

Our full-service capabilities cover all aspects of brake press repair and optimization, including:

- Hydraulic pump and cylinder rebuilding

- Ram and bed alignment and leveling

- Back gauge adjustment and calibration

- Valve, hose, and seal replacement

- Electrical and control system troubleshooting

- Safety interlock inspection and repair

- Preventive maintenance scheduling

- Tonnage verification and calibration

We use precision instruments to measure deflection, tonnage distribution, and alignment—ensuring your press performs within optimal tolerance.

Preventative Maintenance Programs

- Hydraulic pressure and fluid checks

- Cylinder and seal inspection

- Ram alignment verification

- Back gauge calibration

- Electrical and control testing

- Lubrication and filter replacement

- Safety and interlock inspection

Scheduled service intervals keep your brake press in peak condition and minimize unexpected breakdowns.

Routine maintenance extends your machine’s life and prevents costly downtime. Our preventative maintenance programs include:

Industries We Serve

- Metal fabrication and forming shops

- Manufacturing and assembly plants

- Maintenance and industrial departments

- Tool and die companies

- Construction and structural steel operations

- Educational and trade institutions

Our brake press repair and service solutions support a broad range of Minnesota industries, including:

Our clients value our ability to combine precision, reliability, and fast turnaround to keep production on schedule.

FAQs

Do you service both mechanical and hydraulic brake presses?

Yes. We repair all types of presses, from small manual units to high-tonnage hydraulic and CNC models.

Can you fix hydraulic leaks or pump failures?

Absolutely. We rebuild and reseal pumps, cylinders, and valves to restore full pressure and smooth operation.

What causes uneven bends or pressure loss?

Usually misaligned rams, worn seals, or hydraulic imbalance. Our technicians diagnose and correct these issues precisely.

Can you align and calibrate a brake press on-site?

Yes. We can perform most alignment and calibration procedures directly at your facility.

Do you provide safety inspections and certifications?

Yes. We check safety interlocks, limit switches, and e-stop systems to ensure compliance and safe operation.

Contact Us

Keep your shop productive and your forming operations precise with brake press repair in Minneapolis from C & C Machine Tool Inc.

- Phone:

(763) 910-3811

- Email:

mandy@ccmachinetoolinc.com

- Address:

(763) 910-3811th Lane Northeast, Blaine, Minnesota, 55449

Hours: Monday–Friday, 7:00 a.m.–5:00 p.m.

From ram realignment and hydraulic rebuilds to complete system calibration, C & C Machine Tool Inc. delivers the expertise and dependability Minnesota manufacturers rely on for safe, consistent brake press performance.